Laser processing

in the battery industry

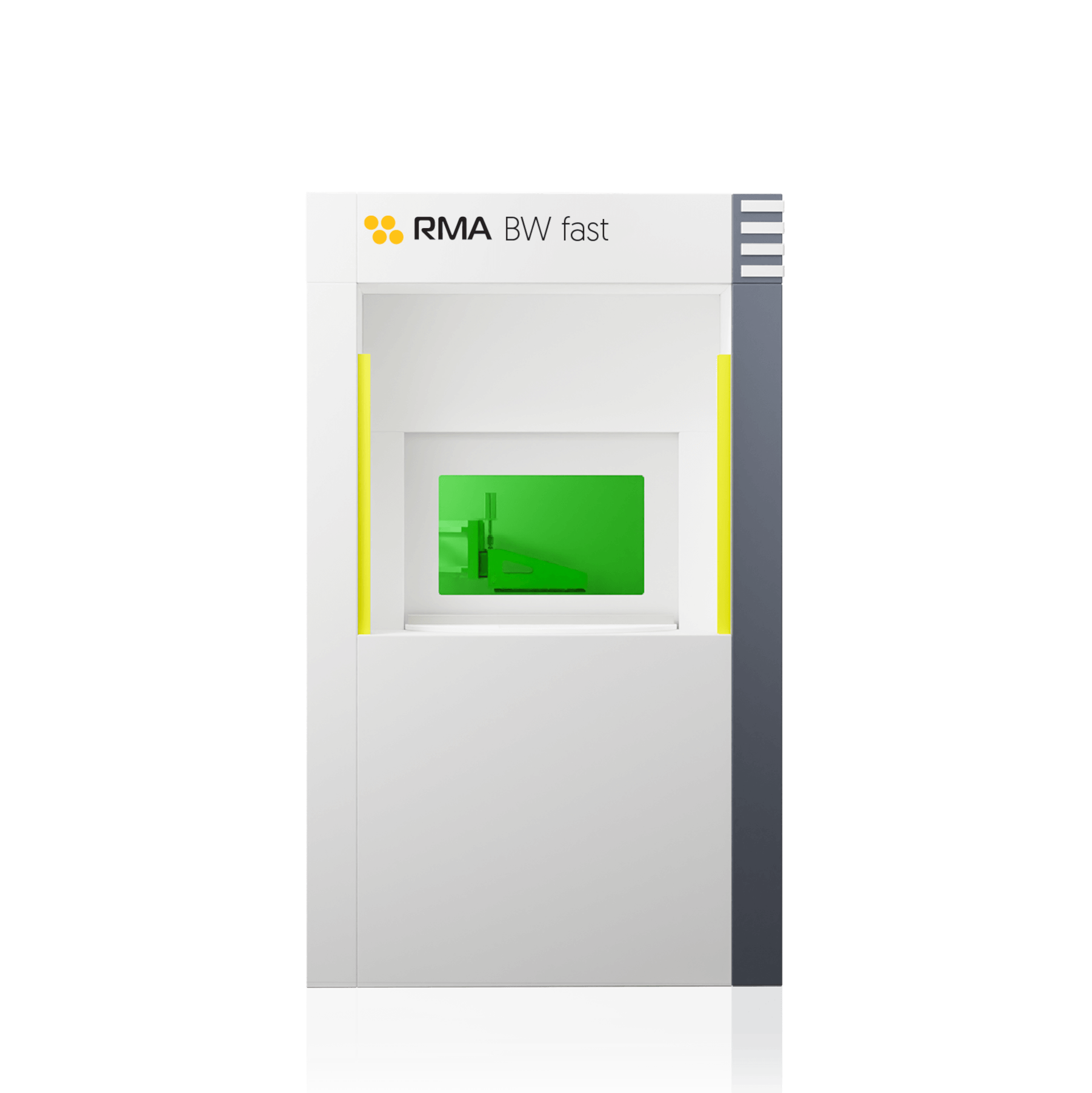

Discover machines from the BATTERY WELDER series

Upcoming events The Battery Show 2024 Europe

June 18-20, 2024 / Stuttgart

For many years, RMA has been a leading provider of comprehensive solutions in the fields of welding automation and laser material processing.

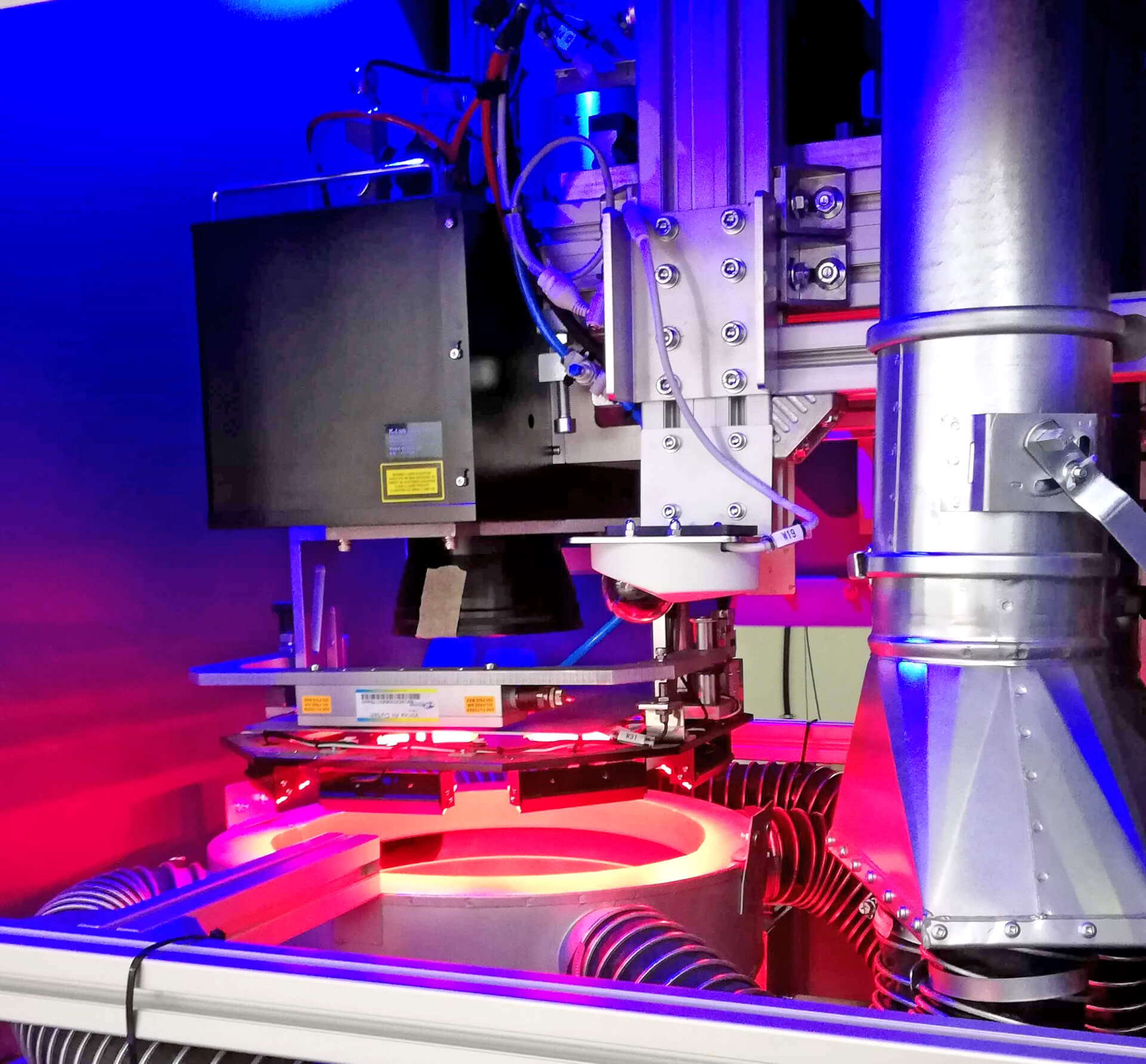

For the battery laser welding industry, we provide ready-made machines for laser welding of battery modules (cylindrical, prismatic, and pouch), as well as custom solutions—production lines and workstations.

In our offer, you can mainly find advanced solutions used in the field of laser welding. As part of our activity, we also carry out advanced projects in the area of 3D laser cutting, laser structuring and laser cleaning.

The projects implemented over the years have made us believe that more and more companies are inclined to use laser sources in their production.

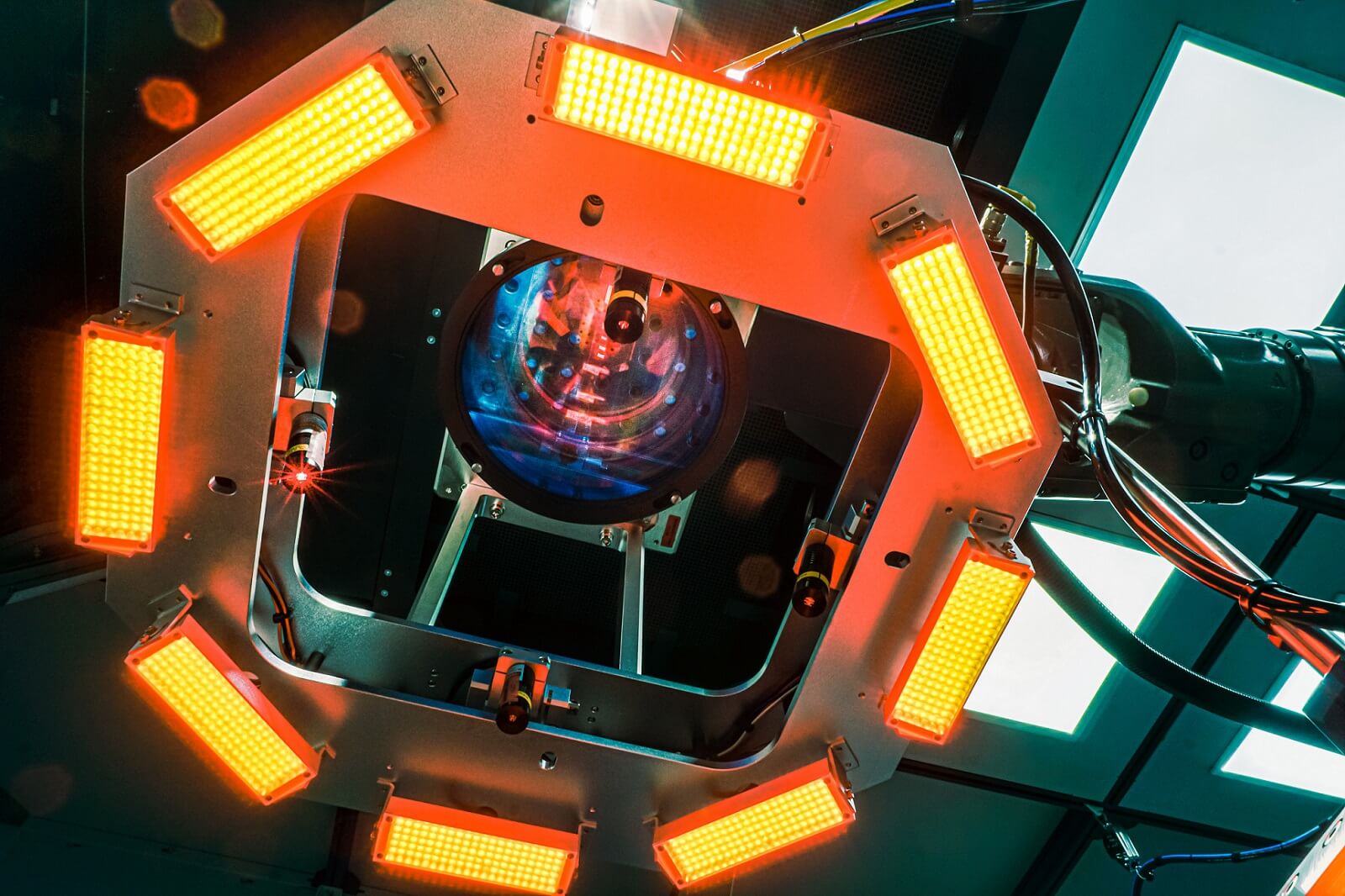

Laser welding is a technology that uses a laser beam to join materials, often in a shielding gas atmosphere. The main advantages of laser welding include: very high process speed, precision, ease of automation, no need for post-processing and high aesthetics of the connection.

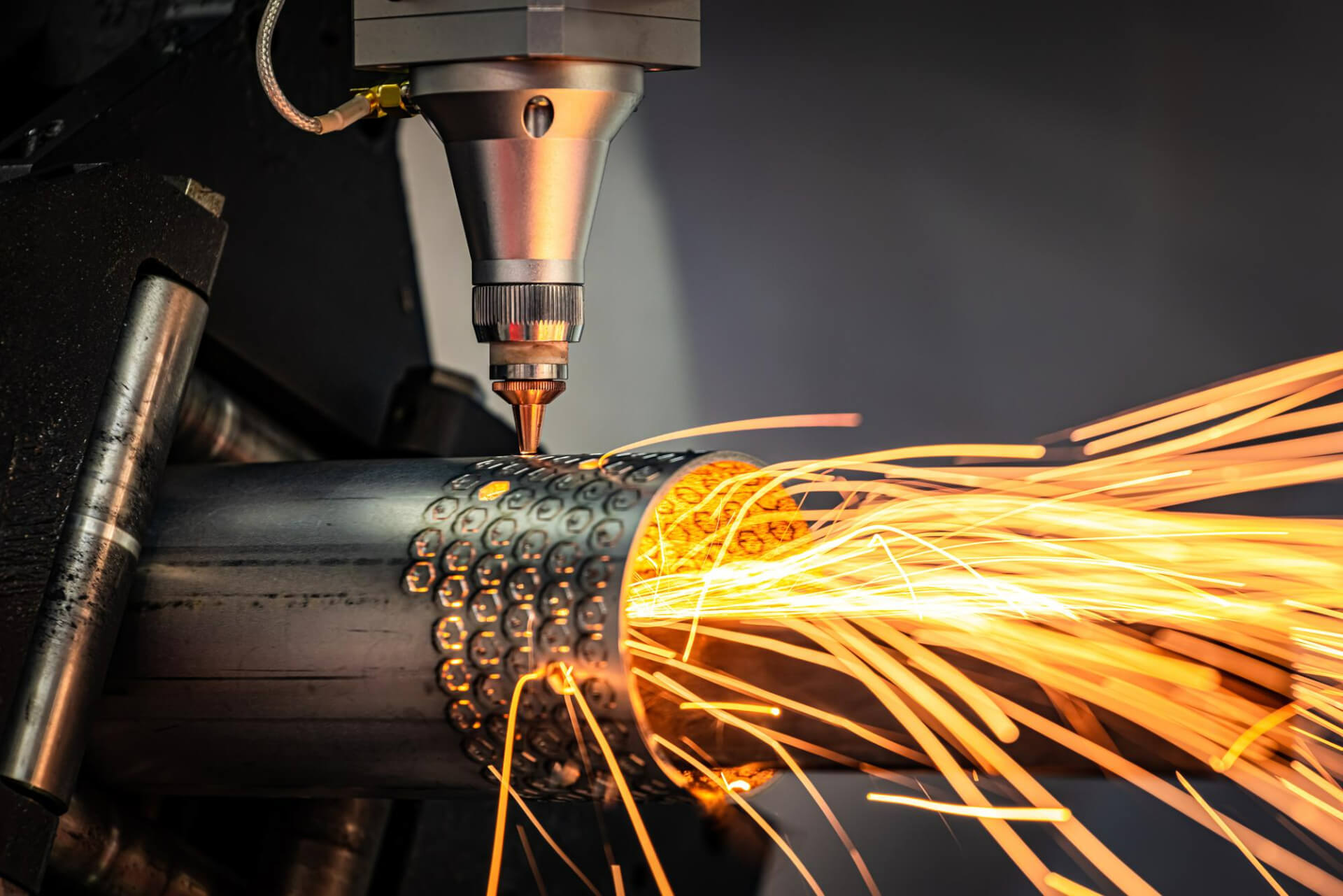

3D laser cutting is a technology that allows the precise cutting of complex shapes and geometry with a laser beam. For this purpose, at RMA, we use a dedicated laser source and a six-axis industrial robot. We also successfully implement projects of special machines for cutting thin-walled profiles (different materials and thicknesses).

Laser cleaning technology uses a highly concentrated laser pulse to evaporate contaminants from the surface of processed objects. In contrast to typical abrasive blasting, laser cleaning technology is characterized by much greater process control with minimal impact on the properties of the cleaned surface.

|

If you're unsure whether laser processes can be a good alternative in your production area, just contact us!

We are constantly developing our knowledge based on the Laser Application Center (LAC), which is located at our headquarters.

There, we carry out technological tests for our Clients and conduct research in new, pioneering areas. For this we use modern laser sources, dedicated processing heads and instrumentation.